In recent years, the aluminium foil container business has emerged as one of the most in-demand sectors in food packaging. These containers are used in everything from airline catering to home baking and food delivery. For importers and distributors looking to expand in this sector, it is crucial to understand how the products are made and what differentiates one supplier from another.

As a manufacturer with deep experience in the aluminium container manufacturing industry, this guide offers firsthand insight into the key elements every buyer should know before placing orders, selecting suppliers, or entering the aluminium foil container making business.

1. Key Quality Indicators Every Buyer Should Evaluate

Before anything else, focus on quality. In aluminium foil container manufacturing, buyers must evaluate several technical parameters to ensure the product meets the intended application and complies with food safety regulations.

✅ Thickness

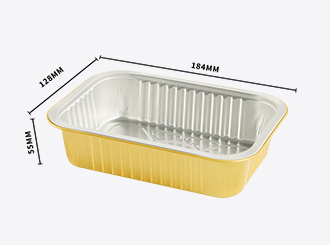

Thickness matters not just for cost but for durability and functionality. Common thickness ranges from 0.035mm to 0.1mm. Thicker foil provides better rigidity and is more suitable for heavier food items, while thinner foil works well for lightweight or short-term use.

✅ Hardness

Foil hardness is classified as soft, half-hard, or hard. Each has its application. Soft foil is ideal for wrapping and sealing, while hard foil offers rigidity and structure—ideal for ready-meal containers and baking trays.

✅ Coating and Surface Finish

Some containers require coatings (such as non-stick or anti-corrosion layers), especially for acidic or oily foods. A clean, glossy surface without wrinkles or contamination is also a sign of high manufacturing standards.

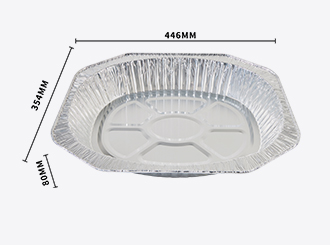

✅ Ribbing and Design Integrity

Embossed ribbing adds strength without increasing material thickness. It also helps maintain shape during transport and handling. High-quality dies and presses produce sharp, uniform edges and curves.

When evaluating

aluminum foil tray manufacturers, request physical samples and compare these factors. In the aluminium foil container manufacturing business, the details determine your customer's satisfaction—and your repeat orders.

2. MOQ, Lead Time, and Packaging: What to Ask Upfront

Managing inventory and delivery schedules starts with understanding your supplier's production capabilities.

✅ Minimum Order Quantity (MOQ)

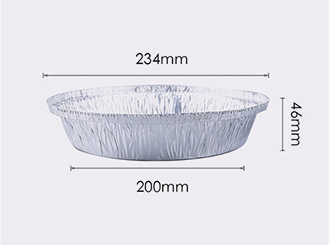

Most factories set MOQs based on container size, mold availability, and material use. A standard MOQ might range from 50,000 to 100,000 pieces for regular sizes. Custom shapes or private label designs typically require higher volumes.

For distributors entering the aluminium foil container business, starting with commonly used sizes (450ml, 750ml, 1000ml trays) can reduce MOQ requirements and ease your entry into the market.

✅ Lead Time

A factory's average lead time depends on capacity, order size, and customization requirements. Generally, expect 2–4 weeks for production after deposit. However, this can extend during peak seasons or holidays.

Clarify production time, packaging time, and loading schedule. In the aluminium foil container manufacturing business, time is a key factor in building strong customer relationships.

✅ Packaging Options

Export-ready packaging should be:

- Stacked and shrink-wrapped for hygiene

- Packed in strong corrugated cartons (often 500–1000 pcs/ctn)

- Labeled with product specs, batch number, and safety instructions

Some suppliers offer retail-ready boxes or bulk packaging, depending on your distribution model.

3. Customization: Build Your Brand with Flexible Options

Customization is a game-changer in the aluminium foil container business plan. Whether selling under your own brand or offering bespoke solutions to large buyers, look for a supplier that supports design flexibility.

✅ Embossing and Molding

You can request embossed logos or patterns on the container surface, enhancing your brand visibility. Custom molds allow you to offer unique shapes or compartment trays. While mold costs can range from $500–$2,000, they’re a one-time investment for long-term branding.

✅ Private Label and Printing

Some factories offer custom-printed lids or outer cartons with your company logo, product images, or barcodes. This is especially valuable for supermarkets or food service chains.

✅ Die Customization

For volume buyers, customized die sets let you differentiate your product offerings. While this step requires close communication and technical input, it elevates your position in the competitive market.

In the aluminium foil container making business, offering tailored solutions often secures repeat orders and higher margins.

4. Certifications: Trust Through Compliance

Credible manufacturers will have internationally recognized certifications that prove their commitment to quality and safety. Before you commit to a supplier, request the following:

✅ FDA Certification

For food-contact materials exported to the USA and similar markets, FDA compliance ensures the foil meets strict hygiene and composition standards.

✅ SGS Testing Reports

SGS is one of the world's most trusted inspection companies. SGS reports on foil thickness, coating content, and food-safety performance can validate a supplier's claims.

✅ ISO Certifications

An ISO 9001 certificate confirms the factory maintains a quality management system and adheres to consistent production processes.

✅ Additional Documents

- MSDS (Material Safety Data Sheet)

- Test reports for recyclability

- European standard compliance (e.g., LFGB)

As an importer or distributor in the aluminium foil container business, using certified suppliers reduces your risk of customs delays, product recalls, or legal issues.

5. Freight, Logistics, and Pricing Strategy

Once your order is ready, the next challenge is getting it to your destination affordably and efficiently. Understanding logistics and pricing strategy can significantly affect your profit margins.

✅ Freight Options

- FOB (Free on Board): You handle shipping after goods are loaded at the port.

- CIF (Cost, Insurance, Freight): The supplier arranges everything up to your destination port.

- DDP (Delivered Duty Paid): For distributors wanting a hands-off approach, some suppliers offer all-inclusive door-to-door delivery.

Freight costs fluctuate based on fuel prices, demand, and global events. Request quotes from multiple freight forwarders and confirm whether your supplier has export experience.

✅ Container Loading Efficiency

Ask how many units fit into a 20ft or 40ft container. A factory that maximizes carton arrangement will save you thousands over the course of a year.

✅ Pricing Factors

The final cost of aluminum containers depends on:

- Aluminum price index (subject to daily changes)

- Labor and electricity costs

- Container size and material thickness

- Customization (e.g., mold use, printing, packaging)

Reliable suppliers will offer tiered pricing based on volume. If you're building a long-term aluminium foil container manufacturing business, negotiate better rates for annual contracts or repeat orders.

6. Strategic Buying Builds Business Success

In summary, importers and distributors must go beyond the surface when sourcing from an aluminium foil container factory. By understanding product specifications, evaluating supplier capabilities, requesting certifications, and optimizing logistics, you protect your investment and build a reputable business.

The aluminium foil container manufacturing business is dynamic and growing, but success depends on preparation and supplier partnership. When you know what to ask, what to inspect, and how to plan, you move from being a buyer to being a leader in the industry.

Whether you're creating your first aluminium foil container business plan or scaling your current operation, these insights offer the clarity and confidence needed to grow effectively in today's global market.