Why Lid Selection Matters More Than You Think

For aluminum foil container importers and distributors, the container itself often gets the most attention. Thickness, alloy, shape, and capacity are carefully evaluated. However, the lid is just as critical as the container—sometimes even more so.

Choosing the wrong plastic lids for aluminum pans can lead to customer complaints, heat deformation, leakage, poor food presentation, or regulatory issues. On the other hand, choosing the right foil container lids improves user experience, protects food quality, and strengthens your brand reputation.

In today's global food packaging market, three plastic lid materials dominate:

- OPS (Oriented Polystyrene)

- PP (Polypropylene)

- PET (Polyethylene Terephthalate)

Each material behaves differently under heat, pressure, and storage conditions. This article explains how these three materials differ, why certain aluminum foil containers are matched with specific lids, and how you—aluminum foil container importers and distributors—can choose the right aluminum container lid for each market and application.

Understanding the Role of Plastic Lids for Aluminum Foil Containers

Before comparing materials, it is important to understand what lids must achieve in real-world use.

A high-quality aluminium container lid must:

- Fit securely on the foil rim

- Maintain food hygiene and freshness

- Withstand temperature changes during transport

- Match the food's temperature (hot or cold)

- Offer visual appeal for retail display

- Meet food-contact safety standards

Because aluminum foil containers are often used for takeaway, catering, airlines, bakeries, and ready meals, the lid must align with how the food is prepared, stored, transported, and reheated.

Overview of the Three Main Plastic Lid Materials

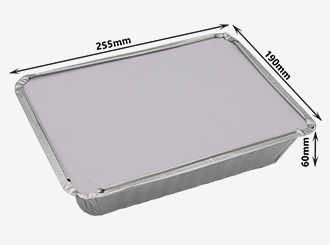

In the global market, the following pairing is most common:

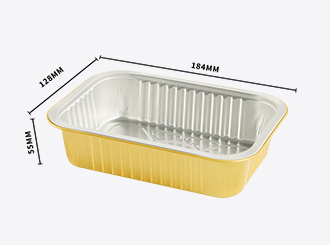

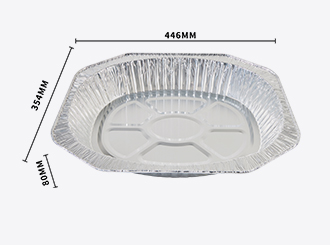

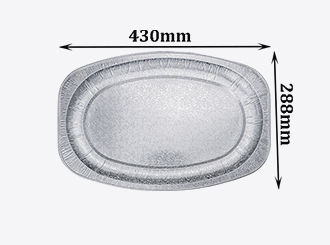

- Silver aluminum foil containers → OPS lids

- Gold aluminum foil containers → PP lids

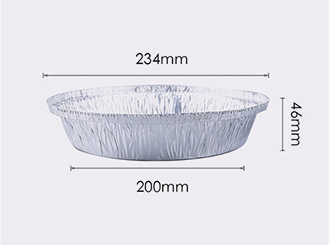

- Small gold aluminum foil containers → PET lids

This pairing is not random. It reflects the technical strengths and weaknesses of each material.

Let's examine them one by one.

OPS Lids: Cost-Effective and Crystal Clear

What Is OPS?

OPS (Oriented Polystyrene) is a stretched polystyrene material that offers excellent transparency and low cost. It is widely used for foil pan covers on silver aluminum containers.

Key Properties of OPS Lids

- Very high clarity for product display

- Lightweight and rigid

- Limited heat resistance (about 80–90°C)

- Not microwave-safe

- Not oven-safe

Why OPS Is Commonly Used for Silver Containers

Silver aluminum foil containers are often used for:

- Cold food

- Bakery items

- Ready-to-eat meals

- Supermarket takeaway packaging

In these scenarios, food is typically not reheated with the lid on. The main goal is visual presentation and cost control, which makes OPS an ideal choice.

Advantages for Importers and Distributors

- Lowest unit cost among plastic lids

- Excellent shelf presentation

- High market acceptance in Europe, Middle East, and Asia

- Easy to stack and transport

Limitations to Be Aware Of

OPS cannot handle high temperatures. If end users microwave food with the lid on, deformation may occur. Therefore, OPS lids should always be marketed clearly as non-microwave lids.

Best use:

Cold food, bakery, deli, takeaway display packaging.

PP Lids: The Best Choice for Hot Food and Reheating

What Is PP?

PP (Polypropylene) is one of the most versatile plastics in food packaging. It is known for high heat resistance and flexibility, making it ideal for hot food applications.

Key Properties of PP Lids

- Heat resistance up to 120–130°C

- Microwave-safe

- Strong and flexible

- Moderate transparency

- Good sealing performance

Why Gold Aluminum Containers Usually Use PP Lids

Gold aluminum foil containers are often positioned as:

- Premium packaging

- Catering trays

- Airline meal containers

- Ready-meal packaging

These applications frequently involve hot filling and microwave reheating, which OPS cannot handle. PP lids solve this problem.

Advantages for Importers and Distributors

- Suitable for hot food markets

- Reduces customer complaints related to deformation

- Strong demand in Australia, North America, and airline catering

- Higher perceived quality

Limitations

PP lids are slightly more expensive than OPS and are not as crystal-clear as PET or OPS. However, functionality outweighs appearance in hot food scenarios.

Best use:

Hot takeaway meals, catering, airline meals, microwave reheating.

PET Lids: Premium Appearance for Small Containers

What Is PET?

PET (Polyethylene Terephthalate) is widely known from beverage bottles. In lid applications, PET offers exceptional clarity and rigidity, making it perfect for small-size containers.

Key Properties of PET Lids

- Highest transparency among all plastics

- High rigidity and crack resistance

- Medium heat resistance (60–70°C)

- Not microwave-safe

- Widely recyclable

Why PET Is Used for Small Gold Aluminum Containers

Small gold aluminum foil containers are often used for:

- Desserts

- Sauces

- Dips

- Small portion foods

In these cases, visual appeal is critical, and food is usually cold or room temperature. PET provides a premium look while maintaining structural strength in small diameters.

Advantages for Importers and Distributors

- Excellent product visibility

- Strong shelf appeal for retail markets

- Ideal for desserts and specialty foods

- Good environmental image due to recyclability

Limitations

PET lids should not be used for hot filling or reheating. Using PET lids incorrectly can result in deformation and customer dissatisfaction.

Best use:

Desserts, cold food, sauces, small portions.

Comparing OPS, PP, and PET at a Glance

| Feature |

OPS |

PP |

PET |

| Transparency |

High |

Medium |

Very High |

| Heat Resistance |

Low |

High |

Medium |

| Microwave Safe |

No |

Yes |

No |

| Typical Container |

Silver foil |

Gold foil |

Small gold foil |

| Cost Level |

Low |

Medium |

Medium-High |

| Best Application |

Cold food |

Hot food |

Premiun cold food |

How Importers Can Choose the Right Disposable Aluminum Pan Lids

When selecting disposable aluminum pan lids, importers and distributors should consider the following factors:

1. Food Temperature

- Cold food → OPS or PET

- Hot food → PP

2. Reheating Method

- Microwave reheating → PP only

- No reheating → OPS or PET

3. Container Size

- Large trays → OPS or PP

- Small trays → PET or PP

4. Market Positioning

- Economy packaging → OPS

- Premium takeaway → PP or PET

5. End-User Education

Clear labeling such as "microwave-safe lid”or "remove lid before heating" reduces misuse and complaints.

Common Mistakes to Avoid When Choosing Foil Pan Covers

Many distributors make avoidable errors, including:

- Using OPS lids for hot food

- Choosing PET lids for microwave meals

- Prioritizing appearance over performance

- Failing to explain lid usage to customers

Avoiding these mistakes protects your brand and reduces after-sales issues.

Final Thoughts: The Right Lid Protects Your Business

Choosing the right aluminum pan covers is not just a technical decision—it is a business decision. OPS, PP, and PET each serve a clear purpose in aluminum foil food packaging.

For importers and distributors, understanding these differences allows you to:

- Match the right lid to the right container

- Reduce customer complaints

- Improve product performance

- Strengthen long-term partnerships

By selecting the correct foil container lids, you ensure that your aluminum foil containers perform exactly as your customers expect—every time.

If you need help matching lid materials to specific aluminum foil container sizes or target markets, Zhengzhou Eming Aluminium Industry, as a professional

aluminum foil container manufacturer can provide technical guidance and customized solutions.