As an international importer or distributor, you constantly look for food packaging products that balance performance, cost, and market acceptance.

Full size steam table pans are one of the most stable and high-demand aluminum foil container categories in the global foodservice industry. From hotels and catering companies to supermarkets and airline kitchens, these pans play a critical role in hot food holding, serving, and transportation.

As a disposable aluminum foil container manufacturer, we understand that choosing the right specifications, depths, and alloys directly affects your success in the market. Therefore, this article explains everything you need to know about full size steam table pans, including dimensions, depth options, applications, and sourcing considerations—so you can make confident decisions for you and your customers.

What Are Full Size Steam Table Pans?

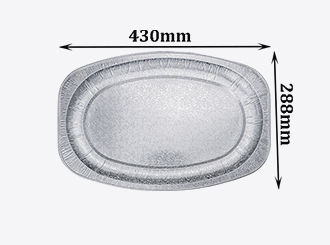

First of all, steam table pans are rectangular food pans designed to fit standard steam tables, chafing dishes, and hot holding equipment. Among all sizes, full size steam table pans are the largest standard format, making them ideal for high-volume foodservice operations.

Because of their versatility, full size pans support a wide range of cuisines and service styles. You can use them for baking, roasting, storing, reheating, and displaying food. Moreover, aluminum foil construction ensures excellent heat conductivity, lightweight handling, and disposable convenience.

Most importantly, full size pans follow international standards, which allows you to sell them across multiple markets without modifying equipment compatibility.

Full Size Foil Pan Dimensions Explained

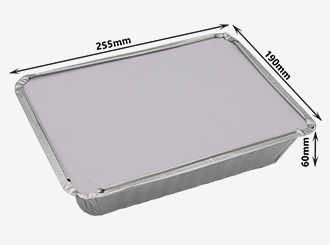

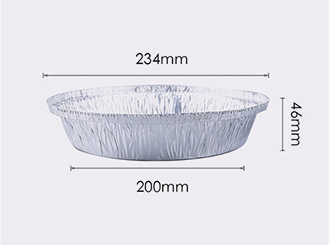

Before you place an order, understanding full size foil pan dimensions is essential. Standardization ensures that the pans fit steam tables, warming trays, and lids correctly.

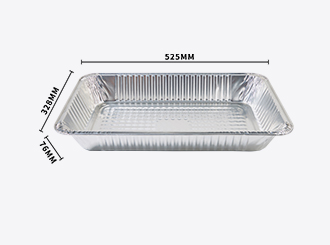

Typically, full size steam table pans measure:

- Length: approximately 20 ¾ inches (525–530 mm)

- Width: approximately 12 ¾ inches (325–330 mm)

However, the depth varies, and this is where product selection becomes critical. While the length and width remain consistent, the depth determines capacity, application, and customer preference.

Because importers often serve multiple foodservice segments, offering a full depth range gives you stronger market coverage.

Full Size Deep Aluminum Pans: Maximum Capacity

When your customers need to serve soups, stews, pasta, rice, or bulk entrees, full size deep aluminum pans become the preferred choice. These pans usually feature depths of around 3 inches (75 mm) or deeper.

Key Advantages

Firstly, deep pans offer higher volume capacity, which reduces refill frequency during service. As a result, they improve operational efficiency in busy kitchens.

Secondly, they help prevent spills during transport, especially for liquid or semi-liquid foods. This benefit matters greatly for catering and takeaway operations.

Moreover, deep aluminum pans maintain heat effectively, ensuring food stays at safe serving temperatures longer.

Typical Applications

- Buffets and banquet halls

- Catering and large events

- Central kitchens and institutional foodservice

Meal prep and food distribution

For you as a distributor, full size deep aluminum pans usually deliver higher unit value and stronger demand from professional buyers.

Full Size Medium Aluminum Pans: Balanced Versatility

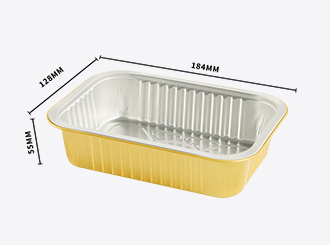

In contrast, full size medium aluminum pans strike a balance between capacity and portion control. These pans generally have depths around 2 to 2.5 inches (50–65 mm).

Why Medium Depth Matters

On one hand, medium pans still hold a substantial amount of food. On the other hand, they reduce waste when serving moderate volumes. Therefore, many restaurants and supermarkets prefer this option.

Additionally, medium-depth pans stack more efficiently, which lowers storage and shipping costs. For international logistics, this advantage directly affects your landed cost.

Common Use Scenarios

- Hot food counters in supermarkets

- Chain restaurants and franchises

- Airline catering

- Prepared meal packaging

Because of their versatility, full size medium aluminum pans often represent the best-selling depth in many regions.

Full Size Shallow Aluminum Pans: Presentation and Control

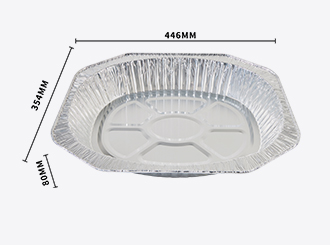

Meanwhile, full size shallow aluminum pans usually have depths of around 1.5 inches (38–40 mm). Although they hold less volume, they serve a unique and important role.

Key Benefits

Firstly, shallow pans allow better food presentation. Customers can see and access food easily, which is ideal for display-oriented service.

Secondly, shallow pans support faster heat transfer. This feature makes them suitable for reheating and short-term holding.

Furthermore, portion control becomes easier, which helps reduce food waste.

Ideal Applications

- Bakery and dessert displays

- Grilled or roasted foods

- Side dishes

- Short-duration buffet service

For you, shallow pans complement deep and medium options, allowing you to offer a complete product line.

Material and Manufacturing Considerations

Beyond size and depth, quality matters. High-quality full size steam table pans rely on carefully selected aluminum alloys and precise manufacturing.

As a manufacturer, we typically use food-grade aluminum foil that meets international safety standards. Depending on the application, different thicknesses ensure the right balance between rigidity and cost.

Moreover, reinforced rims and smooth edges improve strength and handling safety. This detail reduces deformation during transport and usage, which directly impacts customer satisfaction.

For importers, consistent quality translates into fewer complaints, lower returns, and stronger brand reputation.

Lid Compatibility and Packaging Options

Equally important, full size steam table pans must work seamlessly with lids. Common lid options include:

- Aluminum foil lids

- Clear PET plastic lids

Offering lid compatibility increases the value of your product range. Additionally, many buyers prefer bundled solutions, which simplifies procurement.

Packaging also plays a role. Bulk packs suit foodservice wholesalers, while smaller retail packs work better for supermarkets and cash-and-carry channels.

Why Full Size Steam Table Pans Sell Well Globally

From a market perspective, full size steam table pans enjoy steady global demand. Foodservice expansion, catering growth, and takeaway trends continue to drive consumption.

Furthermore, disposable aluminum pans meet hygiene requirements and reduce labor costs associated with washing reusable containers. In many regions, aluminum recycling infrastructure also supports sustainability goals.

For you as an importer or distributor, these factors create long-term sales stability.

How to Choose the Right Manufacturer for You

Finally, selecting the right supplier determines your competitiveness. When sourcing full size steam table pans, you should focus on:

- Consistent full size foil pan dimensions

- Complete depth range: deep, medium, and shallow

- Stable quality and thickness control

- Custom packaging and branding support

- Reliable export experience

By working directly with a manufacturer, you gain better pricing control, flexible customization, and long-term supply security.

A Complete Solution for You and Your Market

In conclusion, full size steam table pans form a cornerstone of the disposable aluminum foil container market. By understanding full size foil pan dimensions and offering full size deep aluminum pans, full size medium aluminum pans, and full size shallow aluminum pans, you position yourself to serve diverse foodservice needs.

Most importantly, when you choose the right manufacturer and product mix, you create value for you, your clients, and their end customers. With the right strategy, full size steam table pans can become a reliable, high-volume product line in your portfolio.